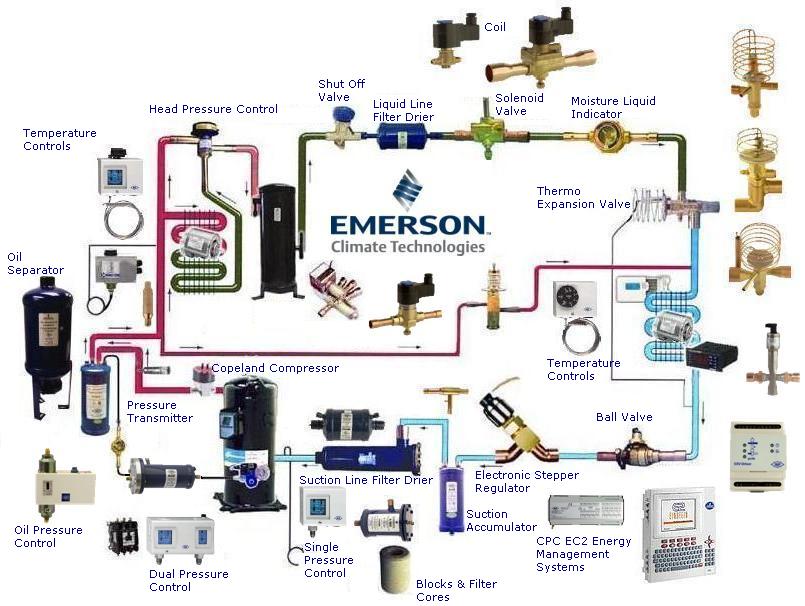

We are an Authorized distributor for Emerson Climate Technologies Flow Controls. Formerly Alco Controls.

Wednesday, December 23, 2009

Monday, December 21, 2009

Friday, December 18, 2009

Monday, December 14, 2009

Copeland Discus Digital Demonstration

Copeland Discus Digital Demonstration: "

"

View the latest in Copeland Discus compressor technology. Learn how the Copeland Discus Digital compressor's unique approach to capacity control can provide precise temperature control, reduced compressor, increase uptime, and reduce your energy costs. | Views: 0 0 ratings | |

| Time: 02:53 | More in Science & Technology |

Monday, November 30, 2009

99% efficiency of oil separation

The High Efficiency Oil Separator features a centrifugal flow path achieving approximately 99% efficiency of oil separation with low pressure drop. Testing by an independent laboratory found that only 0.006% oil by volume was being discharged into the system after leaving a HE oil separator. Virtually oil-free refrigerant gas exists through a fitting just below the lower edge of the oil separator.

Click here

Click here

Sunday, November 29, 2009

Emerson Climate Technologies Introduces Award Winning Copeland Scroll® Outdoor Condensing Unit for Foodservice Refrigeration Applications

Emerson Climate Technologies Introduces Award Winning Copeland Scroll® Outdoor Condensing Unit for Foodservice Refrigeration Applications: "New Condensing Unit Offers Enhanced Energy Efficiency, Reliability and Flexibility in Slim Profile Package"

Thursday, November 26, 2009

Copeland Outdoor Condensing Unit

Copeland Outdoor Condensing Unit: "

"

Jim Mozer, VP Refrigeration Marketing and GM Integrated Products Division, talks about the new Copeland Outdoor Condensing unit from Emerson Climate Technologies. | Views: 202 0 ratings | |

| Time: 04:03 | More in People & Blogs |

Tuesday, November 10, 2009

Place Your Order EARLY!!

Dear Customers,

We'd like you to remind you to place orders early with us. In order to avoid disappointment.

Thank you for your continual support.

From Your local technical and sales support crew.

We'd like you to remind you to place orders early with us. In order to avoid disappointment.

Thank you for your continual support.

From Your local technical and sales support crew.

Sunday, November 08, 2009

Beware! Beware! Beware of Fake EK304

FAKES vs REALS:

Since both boxing, labelling and physical appearance look like the originals.... by taking a closer look it is possible to clarify whether it is a fake.

Buy genuine only! Check with us.

http://www.hintech-electric.com/GenuineEK/

Since both boxing, labelling and physical appearance look like the originals.... by taking a closer look it is possible to clarify whether it is a fake.

Buy genuine only! Check with us.

http://www.hintech-electric.com/GenuineEK/

Thursday, August 06, 2009

Cross Reference

This Competitive Cross Reference provides a cross to the Emerson product from a number of competitors, including Sporlan, Danfoss, Parker, Virginia, A-1 Components, and AC&R Supply.

Download now from http://www.emersonclimate.com/flowcontrols/pdf/Competitive%20Cross%20Reference.pdf

Download now from http://www.emersonclimate.com/flowcontrols/pdf/Competitive%20Cross%20Reference.pdf

Thursday, June 25, 2009

Confirm Your Order ASAP!

Kindly place your order with us as early as possible. So that there is no disappointment. Thank you for your support!

Tuesday, May 19, 2009

Monday, May 18, 2009

Saturday, May 16, 2009

Emerson Flow Controls - A-W & A-F Oil Separators Series

Application

+ Multiple compressor racks for supermarkets and air conditioning

+ Systems with long refrigerant lines

+ Systems with inherent oil return problems

+ Ultra-low temperature systems

+ For use with HCFCs. HFCs and their lubricants

Features

+ Hermetic welded or accessible bolted flange construction

+ Solid copper connections [Stainless steel connections available in special models]

+ Corrosion resistant paint

Specifications

+ Maximum working pressure : 450 psig

+ UL Listed (file #5168)

+ CSA Listed ( LR100624)

Nomenclature

Example : AW 5585 5

A- Series

W- Welded

F- Flanged

5585 - Competitive cross reference

5 - 5/8" connection size

Product Offering

A-W 5582 4 STD A-F 5882 4 STD

A-W 5585 5 STD A-F 5885 5 STD

A-W 5587 7 STD A-F 5887 7 STD

A-W 5588 9 STD A-F 5888 9 STD

A-W 5590 11 STD A-F 5890 11 STD

A-W 5592 13 STD A-F 5892 13 STD

A-W 5602 9 STD A-F 5792 13 STD

A-W 5690 9 STD A-F 5794 17 STD

A-W 5690 11 STD

A-W 5692 13 STD

A-W 5694 17 STD

+ Multiple compressor racks for supermarkets and air conditioning

+ Systems with long refrigerant lines

+ Systems with inherent oil return problems

+ Ultra-low temperature systems

+ For use with HCFCs. HFCs and their lubricants

Features

+ Hermetic welded or accessible bolted flange construction

+ Solid copper connections [Stainless steel connections available in special models]

+ Corrosion resistant paint

Specifications

+ Maximum working pressure : 450 psig

+ UL Listed (file #5168)

+ CSA Listed ( LR100624)

Nomenclature

Example : AW 5585 5

A- Series

W- Welded

F- Flanged

5585 - Competitive cross reference

5 - 5/8" connection size

Product Offering

A-W 5582 4 STD A-F 5882 4 STD

A-W 5585 5 STD A-F 5885 5 STD

A-W 5587 7 STD A-F 5887 7 STD

A-W 5588 9 STD A-F 5888 9 STD

A-W 5590 11 STD A-F 5890 11 STD

A-W 5592 13 STD A-F 5892 13 STD

A-W 5602 9 STD A-F 5792 13 STD

A-W 5690 9 STD A-F 5794 17 STD

A-W 5690 11 STD

A-W 5692 13 STD

A-W 5694 17 STD

Wednesday, May 13, 2009

Thermo Valve Charges

Liquid Charge - L

Liquid Cross Charges - C, Z

Gas Charges - G

Gas Cross Charges - CA

Maximum Operating Pressure - W(MOP)

Check with your wholesalers for typical applications and selection of valve type.

Liquid Cross Charges - C, Z

Gas Charges - G

Gas Cross Charges - CA

Maximum Operating Pressure - W(MOP)

Check with your wholesalers for typical applications and selection of valve type.

Thursday, May 07, 2009

240RA Solenoid Valves

This is a 2-way, normally closed diaphragm valve. 240RA valves are used for liquid, suction, and hot gas service.

Features

Download datasheets

Features

- One coil fits all valve sizes

- Can be brazed into line without disassembly

- Reinforced PTFE diaphragm with woven fibreglass for high temperature applications

- Extended ends for easy installation

- Long Life Molded Coils

- Mounting studs models can be field converted into manual stem

Download datasheets

Thursday, April 23, 2009

Wednesday, April 22, 2009

Solenoid Valves Nomenclature

200RB5T5M AGM120V -

200R VALVE SERIES, B DESIGN, 5/16" PORT SIZE, COPPER EXTENDED ENDS, 5/8" ODF, MANUAL STEM, 12WATT, CLASS F, JUNCTION, STANDARD 120V/50-60HZ

200RB6F5M AGM120V -

200R VALVE SERIES, B DESIGN, 3/8" PORT SIZE, COPPER EXTENDED ENDS, 5/8" SAE, MANUAL STEM, 12WATT, CLASS F, JUNCTION, STANDARD 120V/50-60HZ

200RB6T4M AGM120V -

200R VALVE SERIES, B DESIGN, 3/8" PORT SIZE, COPPER EXTENDED ENDS, 1/2" ODF, MANUAL STEM, 12WATT, CLASS F, JUNCTION, STANDARD 120V/50-60HZ

200R VALVE SERIES, B DESIGN, 5/16" PORT SIZE, COPPER EXTENDED ENDS, 5/8" ODF, MANUAL STEM, 12WATT, CLASS F, JUNCTION, STANDARD 120V/50-60HZ

200RB6F5M AGM120V -

200R VALVE SERIES, B DESIGN, 3/8" PORT SIZE, COPPER EXTENDED ENDS, 5/8" SAE, MANUAL STEM, 12WATT, CLASS F, JUNCTION, STANDARD 120V/50-60HZ

200RB6T4M AGM120V -

200R VALVE SERIES, B DESIGN, 3/8" PORT SIZE, COPPER EXTENDED ENDS, 1/2" ODF, MANUAL STEM, 12WATT, CLASS F, JUNCTION, STANDARD 120V/50-60HZ

Tuesday, April 21, 2009

ARI 730-2005: Flow Capacity Rating of Suction-Line Filters and Suction-Line Filter-Driers

Source: Air-Conditioning and Refrigeration Institute

Scope

This standard establishes a single set of requirements for the testing and rating of ARI standard capacity rating and refrigerant flow rate for refrigerant suction-line filters and filter-driers; whereby, equipment performance can be compared from product to product. The standard covers suction-line filters and suction-line filter-driers in refrigeration and air-conditioning systems.

http://www.ahrinet.org/

Tuesday, April 14, 2009

TI Thermo Valve with interchangeable cartridges

For supermarket cases, walk-in coolers & ice machines applications:

TI[E] thermo valves feature interchangeable cages that provide the capability of changing capacity with the change of a cage. Simply change the easy-to-use cartridges to achieve desired capacity.

- Maximum working pressure: 450psig [3100 kPa]

- 500 hour salt spray resistance per ASTMB117

- Capacities rated in accordance with ARI 750 standards

- Mass spectrometer tested to ensure less than 0.1oz / year R22 [2.5 E-5 std atm/cc/sec] external leakage rate.

Monday, April 06, 2009

Friday, April 03, 2009

Best in class technology

The next time you're installing an EK Filter Drier, make sure you're installing a genuine EK Filter Drier from Emerson Climate Technologies Flow Controls.

Leading Oil Separators

Wednesday, April 01, 2009

Replaceable filter drier blocks and filter cores with STAS

To prevent contamination, do not open can until ready to install.

- Pump down the system and the STAS completely. Warning: System lines must be de-pressurized before attempting to service. Failure to do so can result in system damage and serious bodily injury.

- Remove the cover bolts, cover, and cover gasket (discard old gasket).

- Withdraw the internal assembly by pulling on the handle.

- Disassemble the internal assembly by unscrewing the handle while holding the inlet retainer.

- Remove contaminated filter-drier block. For multiple block units, remove couplings.

- Clean all internal parts thoroughly, giving particular care and attention to outlet screen.

- Remove the block from can and reassemble as rapidly as possible to minimize moisture contamination.

- Replace the screen in the outlet retainer and install the new block or core in the outlet retainer. Make certain that the end of the block with the tapered inside diameter is placed against the outlet retainer. With multiple block units, place coupling between each block or core. Position the inlet retainer over the final block or core, and screw the handle firmly in place. Carefully insert the assembled unit into the shell assembly.

- Lightly coat the new cover gasket with refrigeration oil on both surfaces and carefully place in the groove of the cover.

- Push the cover against the shell assembly. Make certain that the compression spring is against the inlet retainer, and is not handing up on the handle.

- Install 2 cover bolts diagonally opposite holes to hold the cover snugly against the shell edge. Install the remaining bolts snugly.

- Torque all cover bolts evenly in a criss-cross pattern to a torque of 25ft. lbs. maximum for STAS units. For stainless steel bolts in SV series suction line service, the maximum torque is 20ft.lbs.

- Test for leakage.

Saturday, March 14, 2009

Check Valves

The ACK check valve is a normally closed magnetic check valve that prevents reverse refrigerant flow in liquid lines and compressor discharge lines.

FEATURES:

ACK 4 - Check valve series Copper ODF connection sizes 1/4 ODF [in 1/16"]

Download information here.

FEATURES:

- Copper connection sizes: 1/4" through 2-5/8"

- Hermetic spun copper design

- Near zero internal leak rate

- Magnetic checking action

- Built in 30 mesh stainless steel strainer

- Can be installed in any position

- UL/CUL file number : SA 5312

ACK 4 - Check valve series Copper ODF connection sizes 1/4 ODF [in 1/16"]

Download information here.

Friday, March 13, 2009

HX-48 ULTRA HIGH CAPACITY DRIER CORE

For universal replacement. 48 cubic inch desiccant block for use with CFC, HCFC's, HFC's, mineral oil and POE.

100% molecular sieve provides the highest moisture removal for all typical liquid and suction line applications.

Moisture capacity at 75 deg F [24 C] [ Drops of H2O]:

R22 - 1373

R134a - 1565

R404A - 1416

Available at your local wholesalers.

Tuesday, March 03, 2009

Competitive Cross Reference

Emerson Flow Controls is proud to offer this exclusive tool. The Competitive Cross Reference provides a cross to the Emerson product from a number of competitors, including Sporlan, Danfoss, Castel, Henry, Parker, Virginia, A-1 Components, and AC&R Supply. For assistance, contact your local wholesaler.

*Tip: Try entering a broad description. For example, search for SA to find SA-14SU.

Enter as much of the competitor's part number as you know and click Search.

*Tip: Try entering a broad description. For example, search for SA to find SA-14SU.

Enter as much of the competitor's part number as you know and click Search.

Saturday, February 21, 2009

200RB Replacement Parts

1. Complete Kit - enclosing tube and collar body gasket, spring plunger, piston assy,

2. piston ring.

3. Enclosing Tube Kit - Enclosing tube assy, body gasket.

4. Gasket kit - Body gasket

5. Manual Stem - Manual stem assy, seal cap, gasket

6. Body.

7. Bracket adaptor.

Hot site: http://solenoids.9f.com/

Thursday, February 12, 2009

TIR, TER, THR, TMR, ZZ, TRAE, XC-726 Thermal Expansion Valve Customers

Prior to May 28, 2007 production, the power assemblies of the above models were manufactured with a yellow dichromate coating for corrosion protection. While the Cr+6 in the coating is within acceptable levels for compliance with the Restriction of Hazardous Substances (RoHS) international directive, Emerson has elected to change to a plating process completely free of Cr+6.

On May 28, 2007, production will change from the yellow dichromate coating to a silver-blue zinc plating. This plating is also in compliance with RoHS.

This change will not affect the fit, form, or function of the models, including corrosion protection. The change is detectable by the visual appearance difference noted.

Trouble shooting a TXV

Many expansion valves are returned to their manufacturers due to a perceived malfunction, but in reality the problem is in the system, not the valve. [More]

Liquid must be going to the TXV in order for the valve to work properly. If the line contains too much vapor, that could be causing the valve’s apparent malfunction.

Monday, February 09, 2009

240RA 200RB 100RB Solenoid Valves 电磁阀

240RA 9T 9M

Refrigeration solenoid valve.

MWP:500

MOPD: 300#

Fluid Temp: 250

Connections: ODF Extended

Style: Straight

Nominal liquid capacities:

R12 19.6 tons

R134a 23.6 tons

R22 30.5 tons

R407C 29.0 tons

R502 19.8 tons

R404a 21.0 tons

R410a Ask Wholesaler

Assembled in Mexico

Hot site: http://solenoids.9f.com/

Solenoid valves: Operation, selection, and application.

A full understanding of solenoid valves and some selection and installation tips will help to avoid trouble and provide an optimum application. [More]

Monday, February 02, 2009

One valve for ALL applications

The EX electrical control valve can be used in different control tasks.

The ideal mounting position of control valves is with motor downward.

- expansion valve for superheat control

- suction pressure control for capacity control

- liquid injection for desuperheating of compressor

- condensing pressure control

- hot-gas bypass control to compensate excess compressor capacity and to ensure evaporating pressure does not go below a set point.

The ideal mounting position of control valves is with motor downward.

Monday, January 26, 2009

Wednesday, January 21, 2009

How to choose a reliable Alco Controls reseller?

1) The reseller should be an Alco Controls oriented store.

2) The reseller should have a reasonably good knowledge of their products that will answer your questions regarding size selections, installations, trouble-shooting and certainly help you make a wise purchase.

3) If you stick to a reseller that is really an Alco Controls oriented store, that is totally focusing on Alco, you have a better chance of ensuring what the sales staff are talking about. If a store specializes in 20-30 different things, how good are they in any one of those things? But you come into a store that specializes in 1-2 things, you have a better chance of getting the correct products for your job. Refrigeration applications are different. That’s why we focus on giving you the right components ~ selected for specific application. With us value isn't just how much you save, but how much more you receive!

2) The reseller should have a reasonably good knowledge of their products that will answer your questions regarding size selections, installations, trouble-shooting and certainly help you make a wise purchase.

3) If you stick to a reseller that is really an Alco Controls oriented store, that is totally focusing on Alco, you have a better chance of ensuring what the sales staff are talking about. If a store specializes in 20-30 different things, how good are they in any one of those things? But you come into a store that specializes in 1-2 things, you have a better chance of getting the correct products for your job. Refrigeration applications are different. That’s why we focus on giving you the right components ~ selected for specific application. With us value isn't just how much you save, but how much more you receive!

Tuesday, January 20, 2009

Sunday, January 18, 2009

Friday, January 16, 2009

Differential Pressure Controls Series

FD113 oil pressure safety control senses the effective oil pressure on pressure lubricate compressors. If inadequate oil pressure exists, a time delay is energized. If oil pressure does not recover to safe levels within the time delay setting, the compressor is shut down. The time delay allows the compressor adequate time to establish oil pressure on start up and avoids nuisance shutdowns on pressure drop of short duration during the run cycle.

FD113 uses the pressure differential between the 2 inputs to operate and electrical switch. For application in refrigeration and air-conditioning systems according to EN378. Compressor oil pressure control.

Maximum application flexibility is assured by providing an adjustable differential pressure switch which can be adjusted to the compressor's minimum required oil pressure needs and an adjustable electronic time delay which allows you to select the length of time the compressor runs below the minimum pressure before shutdown.

The minimum pressure setting and time delay values specified by the compressor manufacturer should be used when installing the FD113 control.

- Pressure range adjustable from 4 to 65 psid; timer start pressure - timer stop pressure is 3psid above timer start pressure.

- A SPDT switch is used in the pressure portion of the control which allows the addition of a 'safe-light' is desired.

- Electronic timer is time-adjustable from 20 to 150 seconds, supply voltage - 24 to 240Volt AC/DC; timing unaffected by voltage or ambient temperature variations.

- A SPDT manual reset switch is used in the timer module; upon time-out, the compressor is stopped and an alarm circuit is energized; to restart the compressor and de-energize the alarm circuit, the reset button is pushed.

- A factory installed jumper allowed the FD113 to be powered from a single source power; should separate circuits be desired for the timer and 'lockout' switch, the jumper can be removed.

- Agency approvals include: UL/CUL file number E85974, VDE0631/0660, Tuv, CE73/23/EWG, CE93/68/EWG.

Subscribe to:

Posts (Atom)